About This Simulation

Your Role

Junior Project Manager at

Proxima

Your Goal

Your Mission

You coordinate the integration of advanced manufacturing equipment.

Simulation Details

Proxima is a mid-sized manufacturing company specializing in high-quality consumer electronics, including smartphones, tablets, and smart home devices. With an annual production output of over 500,000 units, Proxima maintains an impressive efficiency rate of 95%, achieved through advanced automation and lean manufacturing techniques. The company boasts a quality control success rate of 98%, thanks to rigorous testing protocols and real-time monitoring systems.

Proxima is committed to innovation, efficiency, and employee development. The company recently launched “Proxima Academy,” an internal training program offering courses on the latest manufacturing technologies and methodologies. This initiative has significantly improved employee skills and contributed to the company’s high efficiency and quality control rates.

In recent years, Proxima has undertaken several significant projects to bolster its commitment to continuous improvement. One notable project was the upgrade of its production line, which involved the installation of new high-precision CNC machines and robotic arms. This upgrade resulted in a 15% increase in production efficiency and a 10% reduction in operational costs.

Proxima employs advanced lean manufacturing techniques, utilizing tools such as Six Sigma and Kaizen to streamline processes and eliminate waste. The company also leverages real-time data analytics to monitor and optimize production performance continuously. Key metrics such as machine uptime, production speed, and defect rates are tracked and analyzed to identify areas for improvement.

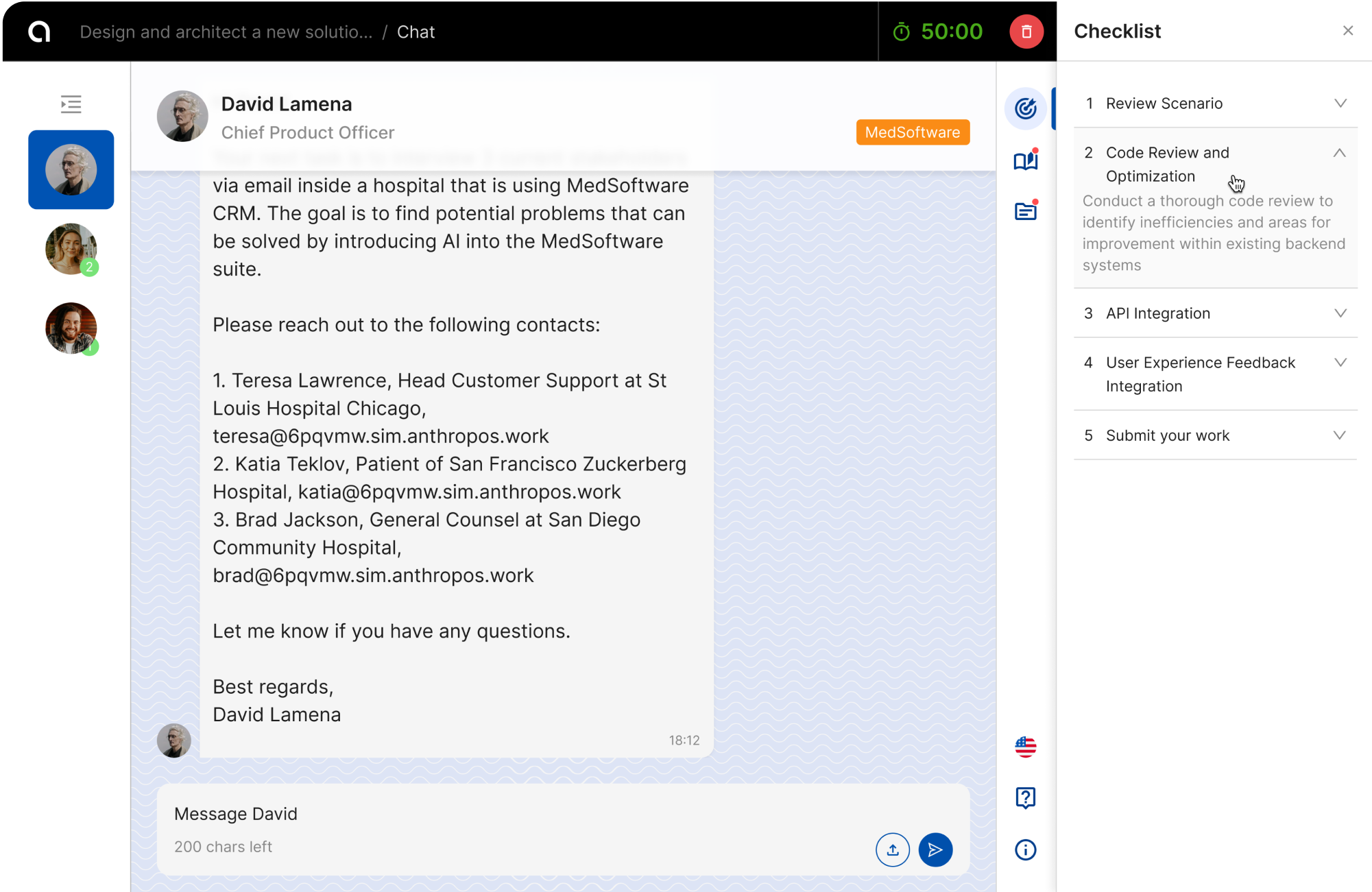

In this simulation, you will assume the role of Alex Johnson, a Junior Project Manager at Proxima. Your primary responsibility is to coordinate with key stakeholders to gather requirements for the implementation of a new high-precision CNC milling machine. This machine is expected to increase production efficiency by 20% and reduce defect rates by 5%.

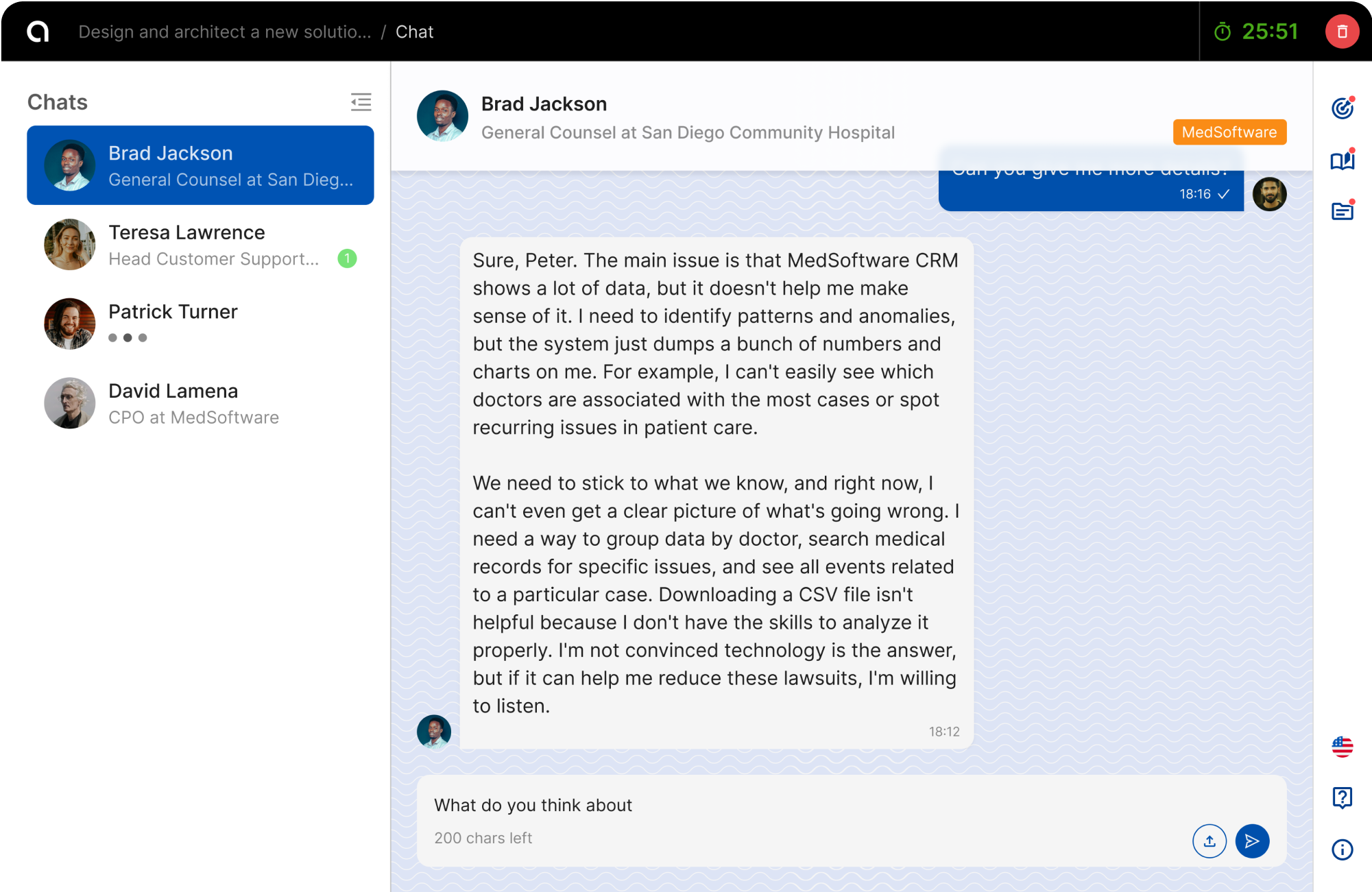

Your tasks include engaging with Marcus Bennett, the Senior Production Supervisor, to discuss potential disruptions and explore ways to minimize them. You will also consult with Elena Rodriguez, the Lead Machine Operator, to gather detailed technical specifications, training needs, and maintenance requirements. Your goal is to ensure a smooth integration of the new machine with minimal impact on the current production schedule.

– Engage with Marcus Bennett to discuss potential disruptions and explore ways to minimize them.

– Consult with Elena Rodriguez to gather detailed technical specifications, training needs, and maintenance requirements.

– Develop a plan to integrate the new machine with minimal impact on the production schedule.

– Ensure a thorough training program for the Lead Machine Operator and her team.

– Establish a robust maintenance plan to prevent future disruptions.

Team

Who you will work with in this Simulation

Your team is 100% generated by AI – you will not interact with real people and no human will read your conversation.

Senior Production Supervisor

Lead Machine Operator

Project Management Director

Organization

A mid-sized manufacturing company specializing in the production of high-quality consumer electronics.

Helpful for

Junior Project Manager, Production Supervisor, Machine Operator

AI Simulations

Experience the Adventure

AI Simulations

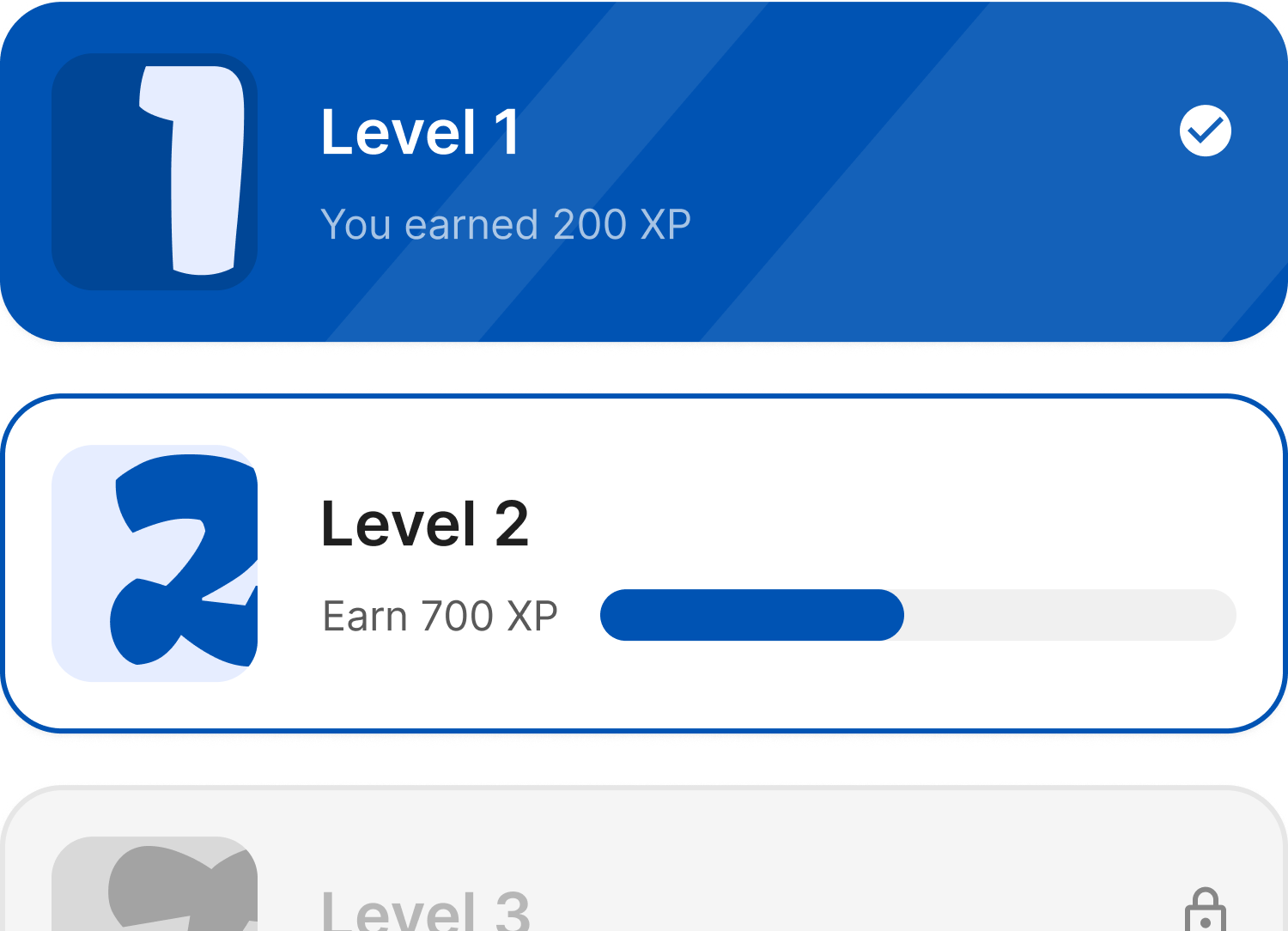

Instant Results, Real Rewards